Selecting the correct type of sharpening steel is crucial for maintaining your knives' performance and longevity. The sharpening steel you choose can significantly impact the knife's cutting edge, affecting everything from its sharpness to its durability. Friedr. Dick offers a wide range of high-quality sharpening steels, each designed to meet specific needs, whether you're a professional chef or a home cook.

Understanding sharpening steel cuts is essential for achieving the desired results. The cut of the sharpening steel determines the surface quality and the level of material abrasion on the knife's cutting edge. Different types of cuts are designed for various levels of abrasion, ranging from high to low. Friedr. Dick offers a broad spectrum of cuts, each tailored to meet different sharpening requirements.

From rough cuts designed for high abrasion to fine cuts meant for straightening the cutting edge, the market offers a variety of options. Friedr. Dick's range includes Diamond, Titanium, Standard, Fine Cut, Polished, and Ceramic types, each with unique characteristics. For instance, Diamond and Titanium cuts offer very high abrasion and are particularly suitable for hard knives. On the other hand, Polished and Ceramic cuts are ideal for straightening and polishing the cutting edge without removing much material.

|

Rough Cut |

For domestic use, high abrasion |

|

Diamond |

Diamond surface for very high abrasion |

|

Titanium |

Special surface for very high abrasion, particularly suitable for hard knives |

|

Standard |

High abrasion |

|

Fine Cut |

Low abrasion/straightening of the cutting-edge |

|

Polished |

No abrasion, only for straightening and polishing the cutting-edge |

|

Ceramic |

Especially suitable for hard knives, very hard but brittle material |

The coarseness or fineness of the sharpened steel cut affects the surface roughness on the sharpened cutting edge. This surface roughness, in turn, influences how the knife interacts with its cutting material. For example, a serrated cutting edge is more effective for cutting through hard foods like crusty bread or fruit skins. In contrast, a smooth cutting edge is preferable for soft foods to avoid crushing them.

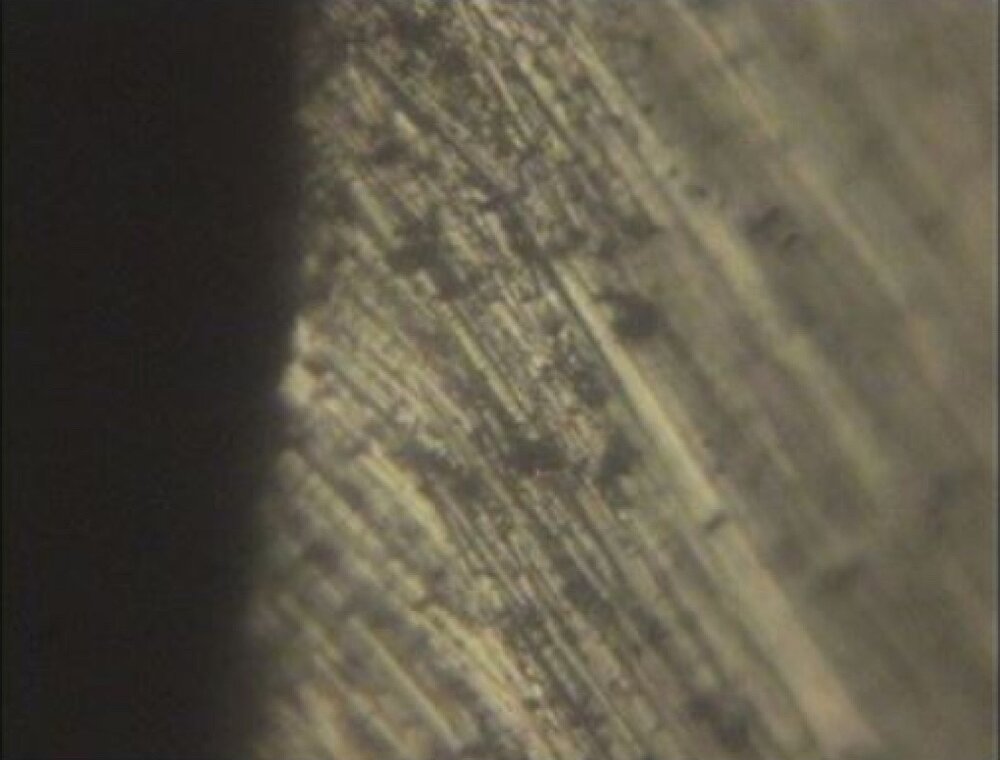

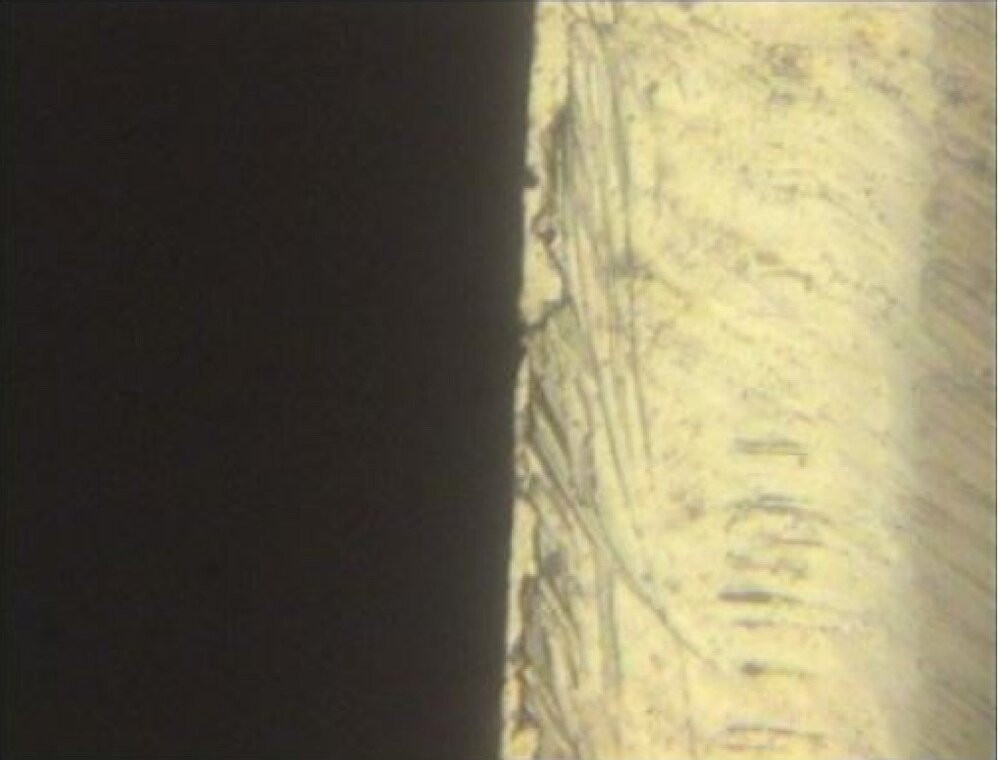

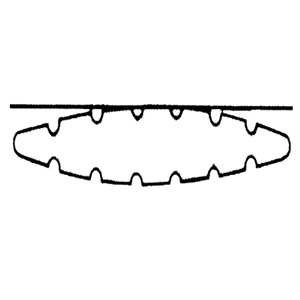

The differences between sharpening steel cuts become even more apparent when examined under a microscope. Friedr. Dick's Diamant (rough) and Dickoron Classic (fine) offer contrasting levels of surface roughness, each serving specific purposes. With its high abrasion, the Diamant cut is excellent for knives that require a more aggressive sharpening approach. In contrast, the Dickoron classic is more suited for fine-tuning and polishing the knife's edge.

Surface roughness - under the microscope

DICK diamant (rough)

DICKORON classic (fine)

The shape of the sharpening steel also plays a crucial role in the sharpening process. Different shapes offer varying levels of contact with the knife, affecting the effectiveness of the sharpening. Friedr. Dick provides a range of shapes, including Round, Oval, Flat Oval, and Square, each designed to meet different sharpening needs.

The Round shape offers a low overall weight and no edges that may damage the cutting edge but provide only a specific contact surface for the knife. Conversely, the Oval shape offers a larger contact surface, resulting in more effective grinding results. The Flat Oval shape is an excellent choice for even greater contact. Friedr. Dick also offers a unique MultiCut/Multiron shape, which provides varying levels of abrasion depending on the pressure applied, making it a versatile option for various sharpening needs.

Round Shape

Low overall weight and no edges that may damage the cutting edge, but only a specific contact surface for the knife.

Oval Shape

Large contact for the knife and, therefore more effective grinding results.

Flat Oval Shape

Linear contact, even greater contact for the knife, and very effective grinding results.

Square Shape

Two steels in one as different cuts are applied opposite each other.

Special shape - MultiCut/Multiron

Seven fine-cut steels in one: The extent of the abrasion from the cutting edge varies depending on the pressure applied to the sharpening steel blade.

Choosing the right sharpening steel involves considering several factors, including the type of knives you own, their material, and their intended use. A Diamond or Titanium cut may be more appropriate for hard knives, while softer knives might benefit from a Fine Cut or Polished sharpening steel. Friedr. Dick offers a range of options, each designed to meet specific sharpening needs, making it easier for you to make an informed choice.

The general rule is that the sharpening steel should always be harder than the knife that is to be sharpened. Sharpening habits also need to be observed. Anyone resharpening a knife frequently can use an even finer sharpening steel. It removes very little material from the cutting edge of the knife and mainly straightens the rolled cutting edge again.

The length of the sharpening steel depends on the length of the knife blade. The sharpening steel should be able to sharpen the entire cutting edge of the knife in one cut if possible. The sharpening steel should be as long as the longest knife blade used.

F. DICK knives and sharpening steels are perfectly matched to one another.

High-quality knife steel with a laser-tested cutting angle and gleaming surface. All sharpening steels from our sharpening steel range are ideal for the ProDynamic. The more often you resharpen, the finer the sharpening steel can be.

Series: ProDynamic

Sharpening steels: All sharpening steels

The forged ActiveCut knives are characterized by their consistent shape and blade design. The double final honing ensures exceptional sharpness. The half bolster enables the entire blade to be re-sharpened. High-quality knife steel with a laser-tested cutting angle and a hardness of 54° HRC. All sharpening steels from our sharpening steel range are ideal for the ActiveCut. The more often you resharpen, the finer the sharpening steel can be.

Series: ActiveCut

Sharpening steels: All sharpening steels

Red Spirit knives are uncompromising in their design when it comes to sharpness. The blades are ground extremely thin, and the cutting edge is polished. The blade is made of a high-quality X50CrMoV15 alloy with a hardness of 56° HRC. All sharpening steels from our sharpening steel range are ideal for the Red Spirit, but we recommend the Red Spirit sharpening steel with a standard cut for this series. The more often you re-sharpen, the finer the sharpening steel can be.

Series: Red Spirit

Sharpening steels: all sharpening steels / Red Spirit sharpening steel with standard cut

The blade is made of a high-quality X50CrMoV15 alloy with 56° HRC. This is synonymous with prolonged edge retention, resistance to wear, and maximum sharpness. All sharpening steels from our sharpening steel range are ideal for the Premier Plus. The more often you re-sharpen, the finer the sharpening steel can be.

Series: Premier Plus

Sharpening steels: All sharpening steels

The blade is made of special X55CrMoV15 German stainless steel with a hardness of 56° HRC. All sharpening steels from our sharpening steel range are ideal for 1905, but we recommend the special 1905 sharpening steel with a standard cut for this series. The more regularly you resharpen, the finer the sharpening steel can be.

Series: 1905

Sharpening steels: all sharpening steels / 1905 sharpening steel with standard cut

Polished, stable blade with a laser-tested cutting edge. High-quality knife alloy with a long cutting-edge lifetime resulted from a homogeneous hardness of 56° HRC, thus significantly reducing material consumption. All sharpening steels from our sharpening steel range are ideal for the ErgoGrip. The more often you resharpen, the finer the sharpening steel can be.

Series: ErgoGrip

Sharpening steels: All sharpening steels

Polished, stable blade with a rounded knife spine and laser-tested cutting edge. High-quality knife alloy with a long cutting edge lifetime as a result - balanced hardness of 56° HRC, thus significantly reducing material consumption. All sharpening steels from our sharpening steel range are ideal for the ExpertGrip. The more often you resharpen, the finer the sharpening steel can be.

Series: ExpertGrip 2K

Sharpening steels: All sharpening steels

Polished, stable blade with a laser-tested cutting edge. High-quality knife alloy with a long cutting edge lifetime as a result - balanced hardness of 56° HRC, thus significantly reducing material consumption. All sharpening steels from our sharpening steel range are ideal for the MasterGrip. The more often you resharpen, the finer the sharpening steel can be.

Series: MasterGrip

Sharpening steels: All sharpening steels

Selecting the right type of sharpening steel is not just about keeping your knives sharp; it's about enhancing their performance and extending their lifespan. Whether you're a professional chef or a home cook, understanding the different types of sharpening steel cuts and shapes can help you make an informed decision. Friedr. Dick offers many high-quality options, each designed to meet specific sharpening needs. So, explore their collection and find the sharpening steel perfect for you.

What are the different types of sharpening steel cuts?

There are various types of sharpening steel cuts, including Rough Cut, Diamond, Titanium, Standard, Fine Cut, Polished, and Ceramic. Each type is designed for different levels of material abrasion on the knife's cutting edge.

How do the different cuts affect the knife's performance?

The cut of the sharpening steel determines the surface quality and the level of material abrasion on the knife's cutting edge. For example, a Diamond cut offers very high abrasion and is suitable for hard knives, while a Polished cut is ideal for straightening and polishing the cutting edge.

What are the different shapes of sharpening steels?

Sharpening steels come in various shapes, including Round, Oval, Flat Oval, and Square. Each shape offers different levels of contact with the knife, affecting the effectiveness of the sharpening process.

How do I choose the right sharpening steel for my knife?

Choosing the right sharpening steel involves considering the type of knives you own, their material, and their intended use. For hard knives, a Diamond or Titanium cut may be more appropriate, while softer knives might benefit from a Fine Cut or Polished sharpening steel.

Is it necessary to use oil or water with a sharpening steel?

No, it is not necessary to use oil or water with most types of sharpening steel. However, always refer to the manufacturer's instructions for specific care and maintenance guidelines.

Can I use the same sharpening steel for all my knives?

While it's possible to use the same sharpening steel for different knives, it's advisable to choose a sharpening steel that matches the specific needs of each knife for optimal results.

What is the MultiCut/Multiron sharpening steel?

The MultiCut/Multiron sharpening steel is a versatile option that provides varying levels of abrasion depending on the pressure applied, making it suitable for various sharpening needs.

How do I maintain my sharpening steel?

Maintaining your sharpening steel involves regular cleaning with a damp cloth and occasional sterilization. Avoid using abrasive cleaners as they can damage the surface of the sharpening steel.

Can I use a sharpening steel on ceramic knives?

It is generally not recommended to use standard sharpening steel on ceramic knives. Ceramic knives require a specific type of sharpening tool designed for ceramic material.