Sharpening steel is a tool designed to maintain the sharpness of your knives, ensuring they are always ready for action. Contrary to popular belief, sharpening steel primarily hones the blade rather than sharpens it. Honing involves realigning the microscopic metal fibers at the edge of the blade, restoring its sharpness without removing significant amounts of metal. This crucial distinction sets it apart from sharpening stones, which are used to create a new edge on dull or damaged blades.

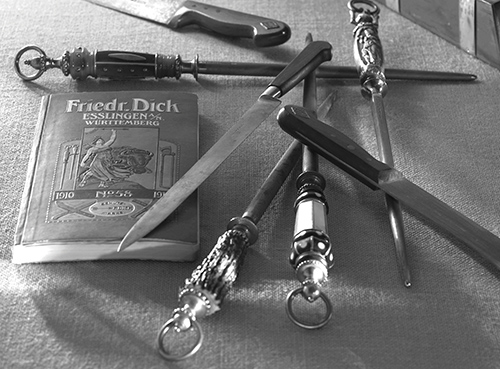

The material used in sharpening steel can vary, the most common being high-carbon steel. However, ceramic and diamond-coated variants are also available, each offering unique benefits. For instance, diamond-coated sharpening steel provides very high abrasion, making it ideal for knives that use heavily. Friedr. Dick, a company with a long history from 1873, specializes in various types of sharpening steel, including those with diamond surfaces.

Understanding the nuances of sharpening steel can significantly elevate your knife maintenance routine. Whether you're a professional chef or a home cook, using sharpening steel regularly can extend the lifespan of your knives and improve your culinary experience.

The concept of sharpening steel has been around for centuries, but it has evolved significantly over the years. Initially, these tools were rudimentary and made from basic materials. However, technological advancements have led to more sophisticated types, including those with specialized cuts and ergonomic designs.

Friedr. Dick has been a significant player in the history of sharpening steel. The company has been producing these essential tools since 1873, exclusively in Germany. Their sharpening steels are renowned for their quality and durability, making them popular among professional chefs and culinary enthusiasts.

Understanding the history of sharpening steel not only adds depth to its importance but also helps you appreciate the craftsmanship that goes into creating these indispensable tools. It's fascinating to see how a simple concept has evolved into a specialized tool that is crucial in kitchens worldwide.

Sharpening steel comes in various shapes and cuts, each designed for specific applications. The most common shapes are cylindrical and oval, but specialized types like flat and square cross-sections are also available. The type of cut can range from fine to standard to diamond, each offering a different level of abrasion.

Friedr. Dick offers a range of sharpening steels with features like ergonomic handles, high-quality fittings, and efficient surface protection. They also provide recommendations for which sharpening steel to use for their various knife series, making it easier to choose the right tool for your needs.

Knowing the different types of sharpening steel can help you make an informed decision when purchasing one. Whether you're looking for a tool with high abrasion or one that offers a fine cut for delicate blades, there's a sharpening steel that's perfect for you.

The benefits of using sharpening steel extend beyond merely maintaining the sharpness of your knives. In professional settings like restaurants, knives are used extensively, sharpening steel is indispensable for ensuring consistent, high-quality cuts. Even in home kitchens, a well-maintained knife can make chopping, slicing, and dicing more efficient and enjoyable.

Friedr. Dick's sharpening steels are especially popular in professional settings due to their durability and effectiveness. Their range includes options with wear-resistant, ultra-hard special coatings, making them suitable for heavy-duty use.

In summary, using sharpening steel is not just a luxury but a necessity for anyone who uses knives regularly. It not only extends the life of your knives but also enhances your overall culinary experience.

One of the most common misconceptions about sharpening steel is that it's used for sharpening knives. As mentioned earlier, its primary function is honing, which differs from sharpening. Honing maintains an already sharp edge, while sharpening creates a new edge on a dull blade.

Another misconception is that all sharpening steels are the same. However, as we've seen, they come in various shapes, cuts, and materials. Friedr. Dick, for instance, offers a range of specialized sharpening steels, including action rods for high abrasion and HyperDrill rods for honing and smoothing the cutting edge.

Understanding these misconceptions can help you make the most of your sharpening steel and avoid common pitfalls. It's essential to choose the right type of sharpening steel for your specific needs and to use it correctly to maintain your knives effectively.

What is sharpening steel?

Sharpening steel is a tool used primarily for honing knife blades. It realigns the microscopic metal fibers at the edge of the blade to maintain its sharpness.

Is sharpening steel the same as a honing rod?

Yes, sharpening steel and honing rod are often used interchangeably. Both are designed for honing rather than sharpening knife blades.

How often should I use sharpening steel?

The frequency of use depends on how often you use your knives. It's advisable to hone your knives before or after each use for regular use.

Can sharpening steel sharpen a completely dull knife?

No, sharpening steel is not designed to sharpen a completely dull knife. You would need a sharpening stone or another more abrasive method.

What materials are used in making sharpening steel?

Sharpening steel is commonly made from high-carbon steel, but ceramic and diamond-coated variants are also available.

What are the different shapes of sharpening steel?

Sharpening steel comes in various shapes, including cylindrical, oval, and even flat or square cross-sections.

How do I clean and maintain my sharpening steel?

Cleaning and maintaining your sharpening steel involves wiping it down with a damp cloth after each use and storing it in a dry place. Some types may require occasional oiling.

Is sharpening steel suitable for all types of knives?

Most types of sharpening steel are suitable for a wide range of knives, but specialized types are designed for specific knife series or materials.

What is the difference between honing and sharpening?

Honing maintains an already sharp edge by realigning the microscopic metal fibers at the edge of the blade. On the other hand, sharpening removes metal to create a new edge on a dull blade.

How do I choose the right type of sharpening steel?

Choosing the right type of sharpening steel depends on your specific needs, the types of knives you have, and how often you use them. Consider factors like abrasion level, shape, and material when choosing.

Sharpening steel is an indispensable tool for maintaining the sharpness and longevity of your knives. Whether you're a professional chef or a home cook, understanding the nuances of sharpening steel can significantly enhance your culinary experience. With various types available, including specialized options from renowned manufacturers like Friedr. Dick, there's a sharpening steel to meet every need and preference.